Rigid resin 607

Name:Rigid resin

Model:607

Colour: multiple colour

Type of packing:Plastic bottle

Packing specification:500g/1000g

light source:LCD/DLP printer for 365-405nm

3d printing rigid photosensitive resin 607

Product Description:

Name: 3D printing rigid standard photosensitive resin

Model: 607

Color: a variety of colors (can be customized)

Package: Bottle

Specification: 500g/1000g

Introduction:

Standard rigid resin 607# can be chosen when making prototypes of strong and rigid parts that need to resist bending. DYOD standard rigid photosensitive resin 607# is an epoxy-based resin. The cured parts have sharp edges, rich details, and can be tapped.

Applicable printers:

LCD 3D printers and DLP 3D printers with LED light source wavelength of 365nm-405nm.

Product features:

01、Fast speed

Standard rigid resin 607# with 4K monochrome 3D printer, effectively shorten the model curing time, layer thickness 25-300 microns, speed up to 2 seconds.

02, High Precision

Designed to print very precise and highly detailed parts, while will show a smooth surface.

03 Low Shrinkage

Designed to reduce volume shrinkage, ensuring dimensional stability of the printed model.

04 Impact resistance

Finished printed models have excellent physical properties, high impact resistance, and can be tapped for parts that require toughness combined with strength.

05、Excellent stability

The liquid resin does not stratify or change color after a long period of time and does not agglomerate, so the printed model is durable and the resin is guaranteed for 12 months.

06.Strong durability

The finished printed model is easy to store. It can be stored in a humid environment without absorbing moisture, and has strong durability.

Technical parameters.

PROPERTY | Unit | PROCEDURE | Results |

Viscosity | (cps@25℃) | 260-350 | |

Critical exposure energy | ( mJ/cm2 ) | 6-7.5 | |

Tensile Strength | MPa | ASTM D638 | 36-57 |

Tensile modulus | MPa | ASTM D638 | 1,799-2,385 |

Breaking elongation rate | % | ASTM D638 | 8-12 |

Notched impact strength | J/m | ASTM D256 | 44-49 |

Heat distortion temperature | ℃ | ASTM D 648 @66PSI | 80 |

Shore hardness | D | 80 |

Note: The above values may vary with part geometry, print settings, temperature changes, secondary post-curing, etc. The actual values may change, so the user must test the product before use to ensure that it will meet your end-use requirements for print performance. The above values are typical values and we do not agree to them as binding material specifications or warranties unless expressly agreed to in writing. The final results depend on the actual use of the user, and this table is for reference only.

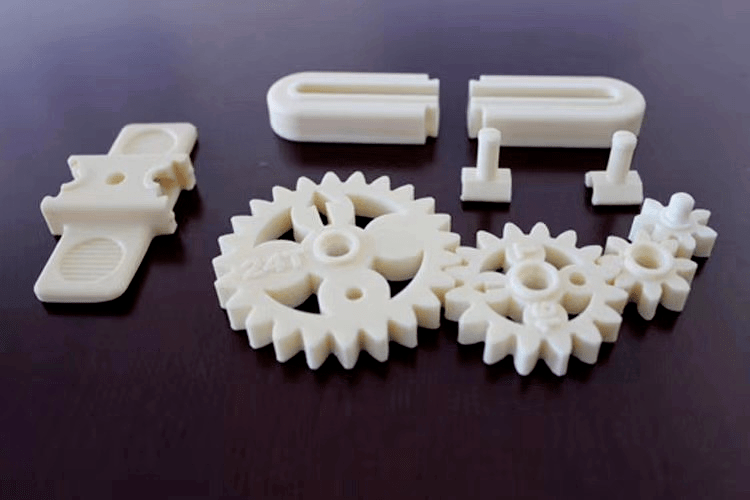

Example model show:

CAUTIONS:.

lShake well before use before pouring into the resin tank.

lSealed in room temperature to avoid high temperature and sunlight.

lThe recommended temperature is 18-35 ℃, a low temperature may affect the printing effect, the resin can be properly preheated before use (not more than 35 ℃).

lIf the resin pigment settles, it can be used after stirring or shaking.

lIt is forbidden to be exposed to strong light sources such as high power and high pressure mercury lamps for a long time.

For safety information, please refer to the MSDS of this product. If you have any problems with your application, please feel free to contact us.

STORAGE AND TRANSPORT:

lThe resin should be sealed and stored in the original package at home temperature in a dark area to avoid high temperature and sunlight.

lThe recommended temperature is 18-35℃, a low temperature may affect the printing effect, the resin can be properly preheated before use (not more than 35℃).

lAfter printing the resin, the resin left in the tank of 3D printer should not be mixed and used with the unused resin. It should be stored in another light-proof container.

lFor safety information, please refer to the MSDS of this product. If you encounter any problems during use, please feel free to contact us.