Flexible resin 609A

Name:3D printing high-quality UV Flexible resin

Model: 609A

Colour: Multiple colour(customized)

Type of packing: Plastic bottle

Packing specification: 500g/1000g

light source:LCD/DLP printer for 365-405nm

3D printing high-quality UV RESIN

Flexible 70A-80A resin

product details:

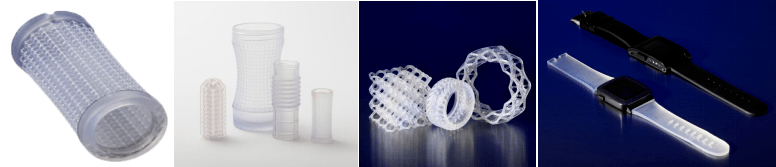

609A flexible resin is a resin with excellent toughness. It is designed to print parts with a balance of softness and strength. Excellent toughness is more reflected in the printed sheet parts, 70A-80A resin can withstand repeated bending, bending and compression. If the model has a thick layer, it will become harder.

The printed model can withstand impact pressure, is resistant to tearing, and can be tapped. This material is very suitable for applications with cushioning, damping and shock absorption properties, such as dental gums.

Introduction:

3D printing silicone resin is a chemical polymer based on alternating chains of silicon and oxygen atoms in 3D printing as liquid silicone rubber (LSR), a highly stable elastomer capable of withstanding extreme temperatures and environments.

Suitable printers:

LCD 3D printers and DLP 3D printers with LED light source wavelengths from 365nm-405nm.

Applications:

Seals, gaskets and plugs, prototyping and low-volume production of small components for medical devices, connectors, consumer and industrial products, anatomical and medical models, custom wearables and ear wear devices.

Product features:

01. High flexibility

Silicone photosensitive resin is easy to bend without breaking, which not only allows it to withstand greater pressure, but also makes it very portable and able to be folded up without any disassembly.

02、Low shrinkage

Specifically designed to reduce volume shrinkage, ensuring the dimensional stability of the printed model.

03、Smooth and delicate surface

Based on the upgraded formula developed by our company, the silicone resin model can show a smooth surface after curing, and the texture is delicate, no pile of material and no roughness.

04、Heat stability

Silicone resin can maintain temperature stability, so the area inside the silicone shielding object will not feel the effect almost as fast as under non-temperature stable materials such as glass.

05、Excellent stability

The liquid resin does not stratify or change color after a long time, does not clump, prints a good model with high durability, and the resin is guaranteed for 12 months.

06、Strong durability

The resin is easy to store. It can be stored in a humid environment without absorbing moisture and is highly durable.

Material property data:

Test project | Test results |

Viscosity | 260-350cps@25℃ |

Critical exposure energy | 9.9-12mJ/cm2 |

Tensile strength(MPa) | 8.5 |

Tensile modulus(MPa) | 6 |

Elongation at break(%) | 100-200 |

Tear strength(KN/M) | 24 |

Thermal deformation temperature(℃) | 10 |

Shaw hardness(A) | 70-80 |

Material property data:

the causes of delamination and discoloration.

In general, ordinary 3D printing resin products will inevitably have the problem of resin lamination at the bottom.

Discoloration ×

This is because some color paste contained in the opaque color resin will precipitate at the bottom after a long time, resulting in the appearance of layered resin at the bottom.

Color stratification ×

Although many businesses advise consumers to thoroughly shake the resin before use so that it can be reused to remove sediment from the bottom. However, if left too long, the sediment can become thicker, making it difficult for consumers to shake well.

Uniform color √

This not only affects the light transmittance of the resin, but also directly affects the curing speed and accuracy of the model, which may lead to printing failure in serious cases.

So our core technology is to try to solve this problem. No matter how long it is placed, there will be no sediment at the bottom, which will not affect the light permeability of the resin, so that the resin can be formed to the best effect.

Require. The above values are typical values and we do not agree with them as binding material specifications or warranties unless expressly agreed in writing. The final effect depends on the actual usage of the user, this table is for reference only.

instructions

l Shake well before use and then pour into resin tank;

l During the use, wear protective gloves and keep the room ventilated;

l This product contains reactive chemicals, avoid contact with eyes, skin and clothing;

l This product have slight irritation on eyes and skin. If you contact your eyes inadvertently, rinse immediately with plenty of water and seek medical advice in time;

l Please wash with soapy water immediately after contacting with skin; wash thoroughly after contacting with clothes before wearing;

l Keep the product away from pregnant women and children.

Storage and transportation

l The resin should be sealed and stored in the original package at home temperature in a dark area to avoid high temperature and sunlight.

l The recommended temperature is 18-35℃, a low temperature may affect the printing effect, the resin can be properly preheated before use (not more than 35℃).

l After printing the resin, the resin left in the tank of 3D printer should not be mixed and used with the unused resin. It should be stored in another light-proof container.

l For safety information, please refer to the MSDS of this product. If you encounter any problems during use, please feel free to contact us.