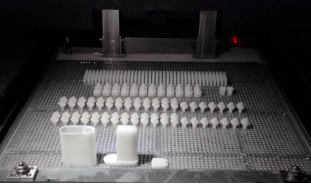

hard and tough resin 703

Name: 3D printing SLA high toughness photosensitive resin

Model:703

Color: white

Package: Barrel

Specification: 5 kg / 10 kg / 20 kg

Hard and tough 3d printing light-curing resin 703

PRODUCTS:

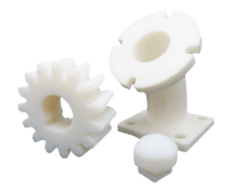

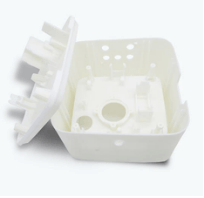

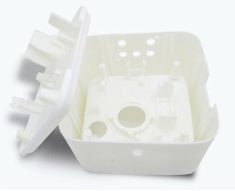

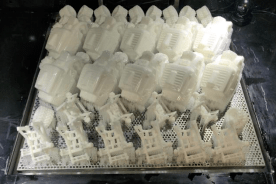

Appearance and texture are virtually indistinguishable from traditional thermoplastics, but with the toughness, accuracy and durability to produce strong, complex parts.

Suitable printers:

Industrial grade SLA 3D printers for wavelengths up to 355nm.

Applications:

Produce robust and practical end-use prototypes such as snap assemblies, automotive housings, impeller and pipe work, and parts that fit consumer electronics.

FEATURES:

01、Durable

This is a durable 3D printing material developed by DareGlobal that has a look and feel that is virtually indistinguishable from traditional thermoplastics. This makes it ideal for the construction of parts and prototypes for functional testing applications.

02、Low Shrinkage

The audited formulation of high tenacity resin type 703 is designed to reduce volume shrinkage, ensuring that the finished printed model remains consistent with the dimensions of the CAD design. Shrinkage ≤1% (tolerance between ±0.03)

03、 High precision

Easy to capture details and achieve maximum restoration of the design structure, but not suitable for making thin-walled parts due to its low elongation at break (minimum wall thickness of 1mm is recommended).

04、High hardness

Cured models with a hardness of 80D provide superior hardness and durability, making them ideal as industrial parts requiring high impact resistance strength.

05、Good Toughness

Due to the upgraded toughness of the model in the upgraded formula, the finished cured prototype is rigid and tough with a balance of wear resistance and scratch resistance.

TECHNICAL PARAMETERS:

PROPERTY | Unit | PROCEDURE | Results |

Viscosity | (cps@25℃) | 288 | |

Critical exposure energy | ( mJ/cm2 ) | 8.1-9.1 | |

Tensile Strength | MPa | ASTM D638 | 40-58 |

Tensile modulus | MPa | ASTM D638 | 2,675-2,780 |

Breaking elongation rate | % | ASTM D638 | 8-12 |

Notched impact strength | J/m | ASTM D256 | 35-42 |

Heat distortion temperature | ℃ | ASTM D 648 @66PSI | 52-63 |

Shore hardness | D | 80 |

Notice:The above values may vary depending on the geometry of the part, printing settings, temperature changes, secondary post-curing, etc. The actual values may vary. Therefore, users must test the product before use to ensure that it can meet your final use of printing performance. Require. The above values are typical values and we do not agree with them as binding material specifications or warranties unless expressly agreed in writing. The final effect depends on the actual usage of the user, this table is for reference only.

CAUTIONS:

lShake well before use before pouring into the resin tank.

lThis resin cannot be mixed with other resins, liquids, substances, etc., otherwise it will lead to printing failure.

lLower temperature may affect the printing effect, so the resin can be properly preheated before use (no more than 35℃).

ll during use, pay attention to wear protective gloves and mask, and keep the room ventilated.

lThis product contains active chemical substances, this product avoid contact with eyes, skin and clothing.

lThis product is slightly irritating to eyes and skin, if it comes into contact with eyes accidentally, please rinse with plenty of water immediately and seek medical attention promptly.

lThis product should be rinsed with soap and water immediately after contact with the skin; wash thoroughly after contact with clothing before wearing.

lAvoid children and pregnant women to contact with this product.

STORAGE AND TRANSPORT:

lThe resin should be sealed and stored in the original package at home temperature in a dark area to avoid high temperature and sunlight.

lThe recommended temperature is 18-35℃, a low temperature may affect the printing effect, the resin can be properly preheated before use (not more than 35℃).

lAfter printing the resin, the resin left in the tank of 3D printer should not be mixed and used with the unused resin. It should be stored in another light-proof container.

lFor safety information, please refer to the MSDS of this product. If you encounter any problems during use, please feel free to contact us.